"Circular Thinking!" generates record turnout

Sustainable packaging solutions in thermoforming

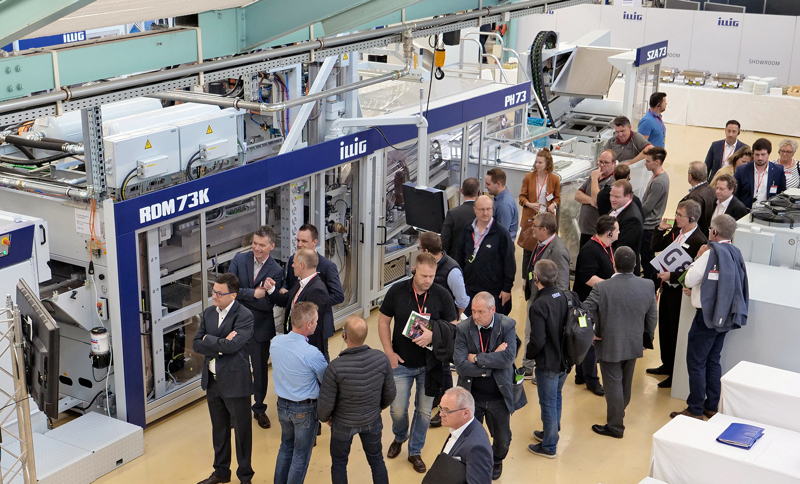

Visitors of the Illig Open house venue in front of the thermoforming machine RDM73K.

Quelle: Illig

Effects of the global discourse on packaging

Sustainability, environmental friendliness, the reduction of plastics and recyclability of packaging are hot topics around the globe, putting pressure on the packaging industry. The topic is still hotly and emotionally debated because of the pollution of the earth's marine life, and the injection of some objectivity is greatly needed. Packaging made of plastic materials or plastic compounds will continue to play an important role in maintaining hygiene standards and in protecting the packaged goods. In particular in developing countries and emerging economies, the demands will only increase due to the continuing urbanization. “In our view, the development of a global circular economy needs, therefore, to be given top priority. That means recyclable packaging and the use of recycled materials in the packaging industry are essential. The developments in the PET bottle industry are exemplary for what is possible,” Karl Schäuble explains to the journalists during the press conference. The commitment of food manufacturers and traders should serve to accelerate the global development of recycling systems for packaging. However, more public awareness and education about the value of plastic and the way to properly handle this resource is still needed.

Packaging development Pactivity®

Within the context of its packaging development concept Pactivity®, Illig has long considered the aspect of the circular economy in the packaging industry and has continually expanded upon the aspect of recycling. Optimized packaging can reduce the amount of resources required and can be realized in a recycling-friendly way. Thermoformed packaging in particular is characterized by thin walls, which requires less resources and less costs to manufacture. Aside from conventional plastics, the use of alternative and newer materials is also possible with thermoforming. Illig's current thermoforming and tool systems can already process, for example, organic-based and biodegradable plastics, recycled materials and compound materials into high-quality recyclable formed parts.

“Especially in combination with the IML-T® technology, a variety of new packaging possibilities have come to life. Among others, the possibility of manufacturing 100% cardboard blister packaging on our packaging machines,” explains Karl Schäuble. Pactivity® also means that Illig configures or even newly develops the optimized production system for the respective packaging. In this development process, the tool systems take on an increasingly important role within the production line. Illig production systems are characterized by their high availability, and they offer multiple options for monitoring and controlling the production process. Several parameters of the tool systems can also increase the output of the entire production line. Illig has developed a thoroughly consistent tool concept: “The tool systems, which generally consist of multiple tools, are developed according to a consistent and standardized strategy. A further step in the digitization of thermoforming in conformity with Industry 4.0,” added Karl Schäuble.

Sustainable packaging solutions at the Open House

The focus of this year's Open House was the current market demands in relation to recycling and tool systems. Especially with the development and continuation of the IML-T® decoration technology, Illig has once again set new milestones in the industry with recyclable monomaterial and the cardboard-plastic combination packaging. The plastic-cardboard-combination packaging IML-T® Cardboard was specially developed for the new market demands for a circular economy and it can be manufactured on the Illig IML-T® unit. The advantage of the newly designed packaging is the ability to easily separate the plastic from the cardboard. This enables simplified recycling. Another advantage of the concept is the manufacturing of 100% cardboard blisters on an HSA 50d heat sealing machine. The blister packaging machine HSU 35 is also new for non-food applications and the pharmaceutical industry.

The Illig Group continues to grow globally. Revenue has increased by a total of 30 percent over the last three years, 2016, 2017 and 2018. This is mostly attributable to the new developments in recent years and the consistent realization of the packaging development concept Pactivity®. “The increase in revenue is not only in Europe, but in particular in the Asian and Western Asian markets, and South America, and is predominantly attributable to the increased demand for packaging machines such as our HSA, BSA and FFS lines,” confirms Karl Schäuble on the economic situation. Illig expects the overall packaging technology market to continue to grow worldwide over the next few years. With the solutions that the company already has in its portfolio, it can make further inroads in additional industries incorporating thermoforming. Despite that, some customers are currently holding back on making new investments due to the global packaging discourse, which is responsible for the reduction of orders in the past few months as compared to the previous year. The number of new projects currently being processed in recent months has increased as compared to 2018, but the final decision to go ahead with the new investments is often pushed back. Because of this, it is in the interest of the entire packaging industry to inject some objectivity into the ongoing public packaging discourse by consistently making use of the existing communication channels. “Raising awareness of eco-balances for individual packaging variants and their recyclability is a difficult process, but it is also the only way to add objectivity to the current discourse. This will calm the uncertainty among consumers and eventually lead once again to an increase in demand in the packaging industry as in previous years,” Karl Schäuble predicts.

Outlook to the K trade fair in October 2019

At the most prestigious plastics trade fair, Illig will be presenting the next developments in the digitization of the thermoforming process in conformity with the new Industry 4.0 standard, in which the Illig tool system will take on an important role. Illig will also be announcing the first thermoforming machine of the 4th generation, which will set new standards in terms of productivity and reproducibility in the thermoforming process. Another new development on hand will be the IML-T® decoration of thermoformed lids. In addition to machine demonstrations, visitors to K trade fair stand can also get the latest on current developments in Illig service.

(st)