An insight into the Bobst industry vision

The backbone of packaging production

Helpline Plus Smart Headset: overlay-manuals providing the right informations on time and hands free to work.

Quelle: Bobst

„The packaging business community is dealing with the unprecedented Coronavirus (COVID-19) situation with both urgency and a deep sense of care. It will come to an end. With many people working from home, we want to provide content about the equipment, systems and processes that we were due to showcase in the coming months, letting you know what is new and expected so that you can plan ahead for your own business,“ Bobst is informing via press information.

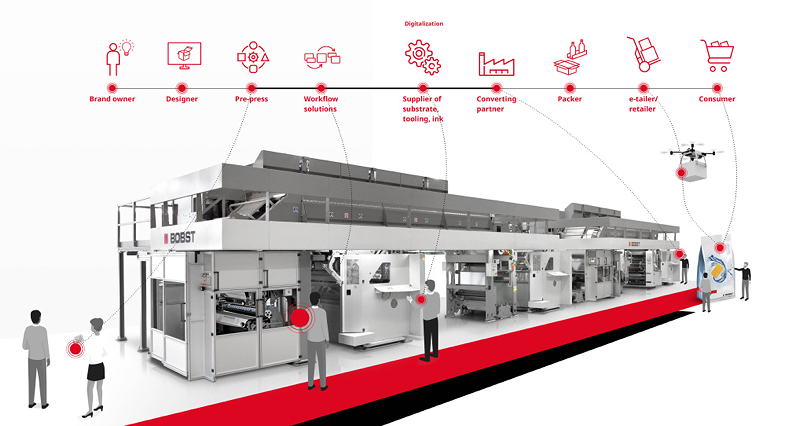

„Brand owners and converters will continue to stay under pressure like never before. A lot of challenges are shaking our industry, such as faster time-to-market, e-commerce, and sustainability. Each of these challenges also means a variety of opportunities for packaging production. Suppliers of packaging equipment and packaging services are leading a necessary transformation in the industry. We built this transformation around four main pillars: connectivity, digitalization, automation and sustainability.

The entire production chain needs to become more agile and flexible. Across the whole production workflow, more fact-based and timely decisions will be required. We are entering a period where connected systems will share data across the entire production process for faster and precise optimization.

From the initial design file to the final produced label or box, all steps of the packaging production will become interlinked. A change at the design stage, whether layout or structural, will automatically be communicated to all next steps downstream. The specific tasks at each stage of the process, such as printing, cutting and folding, will be automated with digitalized solutions, enabling a much faster turnaround time.

How far have we come – and where do we still need to go?

Digitalize, automate and connect: The Bobst vision for coming years.

Quelle: Bobst

The digital transformation is happening at different speeds across the packaging industry. There is a consensus that labels have led the way and, after a slow initial start, there are now more digital label presses sold than conventional printing machines. This is because in the labels industry, we have reached the stage where the digital solutions can deliver results at a satisfactorily comparable quality, productivity and cost level to conventional presses. Moreover, and important to appreciate, labels are less complex to produce than flexible packaging, folding carton and corrugated boxes. The label industry has set the tone for the other industries to follow, each of them with the respective components.

"In the label industry the connectivity and the digitalization has enabled real progress,"" said Christian Zeller – Marketing Director for the Label and Flexible Packaging solutions. "Among other things, you can now track the quality of every single label produced comparing the output with the original PDF and this on any technology – digital, hybrid or flexo."

Towards a fully automated workflow

The digitalization of printing processes is the most visible element in the packaging industry, commented Jean-Pascal Bobst, CEO Bobst Group. The coming years will likely see a major acceleration of digital printing. While the solutions are becoming available, the biggest challenge for printers and converters is not the individual printing machines, but rather the entire workflow encompassing converting.

At BOBST we have a fully automated and controlled workflow from file to the final label, pouch or box, and this solution answers brand owners’ and converters’ needs. With the innovations completed to date and others to come from BOBST and other industry partners, we are moving in the right direction, added Jean-Pascal Bobst.

Packaging production 4.0 will require mindset changes

Digitalization: innovating the value chain

Quelle: Bobst

In a more automated world, the focus will be less on the how and more on the what. This will mean a fundamental change in the types of personnel and skills required throughout the workflow. The data reported back by the machines will require the operators to have the global view of the entire process and no longer to specialize on a given technical task. BOBST is very aware of this fundamental change and offers training and a powerful suite of applications to help operators.

Human knowledge and proximity will always be required. But rather than focusing on repetitive manual or technical tasks, the human input will be more on the value-adding contributions to more automation and better packaging production.

The below is just a sample of the Bobst digital solutions enabling better automation and connection. For label and flexible packaging production, Bobst DigiFlexo technology now enables the automatic control of color quality and consistency, the ability to print across numerous substrates and consume less ink and generate less waste than conventional flexo processes. The DigiFlexo presses operate on the basis of a connected automation workflow by having a data exchange from machine to machine. The complete automation of the printing process avoids machine stops, and the hands and eyes of the operator are replaced by the accuracy of a digitalized data adjustment system.

In 2019, Bobst introduced DigiColor – the very first closed-loop color control system in the flexo industry. Color is measured in-line and adjusted on each print unit to match the target color values. DigiFlexo is the perfect solution for brand owners needing customization, color consistency control and faster time-to-market.

At Labelexpo 2019, Bobst also introduced the Master DM5, a hybrid label press encompassing a digital printing module with the Mouvent Inkjet cluster, which provides the best possible combination of digital and DigiFlexo printing in a single press. It is the most digitally automated press in the label market, with the highest print quality, productivity and reliability for all kind of print jobs – from short to long.

For folding carton, the Accucheck in-line inspection system inspects carton blanks for defects and guarantees complete quality consistency. This enables brand owners to provide perfect boxes to their packers, reducing waste and downtime in the supply chain. Another major innovation is the Digital Inspection Table. It allows the proofing of printed sheets and die-cut blanks, whilst providing real-time visual representations to match real product with digital proofs. It is a novel technology designed to drive productivity and virtually remove print production errors, increasing brand owner satisfaction.

For the corrugated board industry, the Bobst THQ technology enables unmatched high graphics quality at lower cost than conventional offset and flexo processes and in addition offers anti-counterfeit printing capabilities. Premium Gap Control meanwhile, ensures reliable and precise control of 100% of finished boxes at rated production speed, providing optimum productivity and total folding quality.

And complementing all of this is the Connected Services offer. For example, our Helpline Plus service allows customers to connect with Bobst experts immediately as the need arises, meaning that around 80% of all technical issues are resolved remotely within two hours. Other elements of Connected Services include apps to make production- and machine data available by using a mobile, tablet or by using a browser.

Remote Monitoring is a comprehensive production reporting tool designed to quickly access detailed machine production, process and technical data, while Downtime Tracking makes it easy to get accurate root cause stoppage analysis for a specific machine or an entire shop floor.

"The feedback we have had from customers around the Connected are unanimous," said Raphael Indermuehle – Bobst Services Sales & Marketing Head. "They have seen significant enhancements in productivity and quality, with fewer errors and major up-time gains. The benefits of these connected services are considerable."

Conclusion

Brand owners and converters are already seeing the significant benefits of more automation, digitalization and connectivity and more to come soon. Our vision is simple and clear. We want to shape the future of the packaging industry. Across labels, flexible packaging, folding carton and corrugated board, we drive with passion and commitment. We intend to connect all stakeholders to a digitalized and automated workflow, accessing information anytime anywhere for a flexible and agile collaborative operation.

(st)